Low Melting Glass Paste

:: Glass Frit YPF-002 ::

_Standard Spec_

Glass composition : Tin-Phosphate Glass

Low-temperature workability

Excellent optical characteristics

| Model | YPF-002 |

| Tg[℃] | 280-300 |

| Tx[℃] | >450 |

| Tw[℃] | 330-340 |

| CTE[×10-7/℃] | 100-120 |

| W.R[ppm] | 40-50 |

| Refractive index[-] | 1.80 |

| Transmittance[T% at outside] | 82-85 |

| Sintering color | Transmission |

| Gas Permeabilty[g/m2・24hr at H2O] | 0.036-0.041 |

| Young's modulus[Gpa] | 33.2 |

| Vickers hardness[Gpa] | 1.6 |

_Reasons for difficulty in Paste_

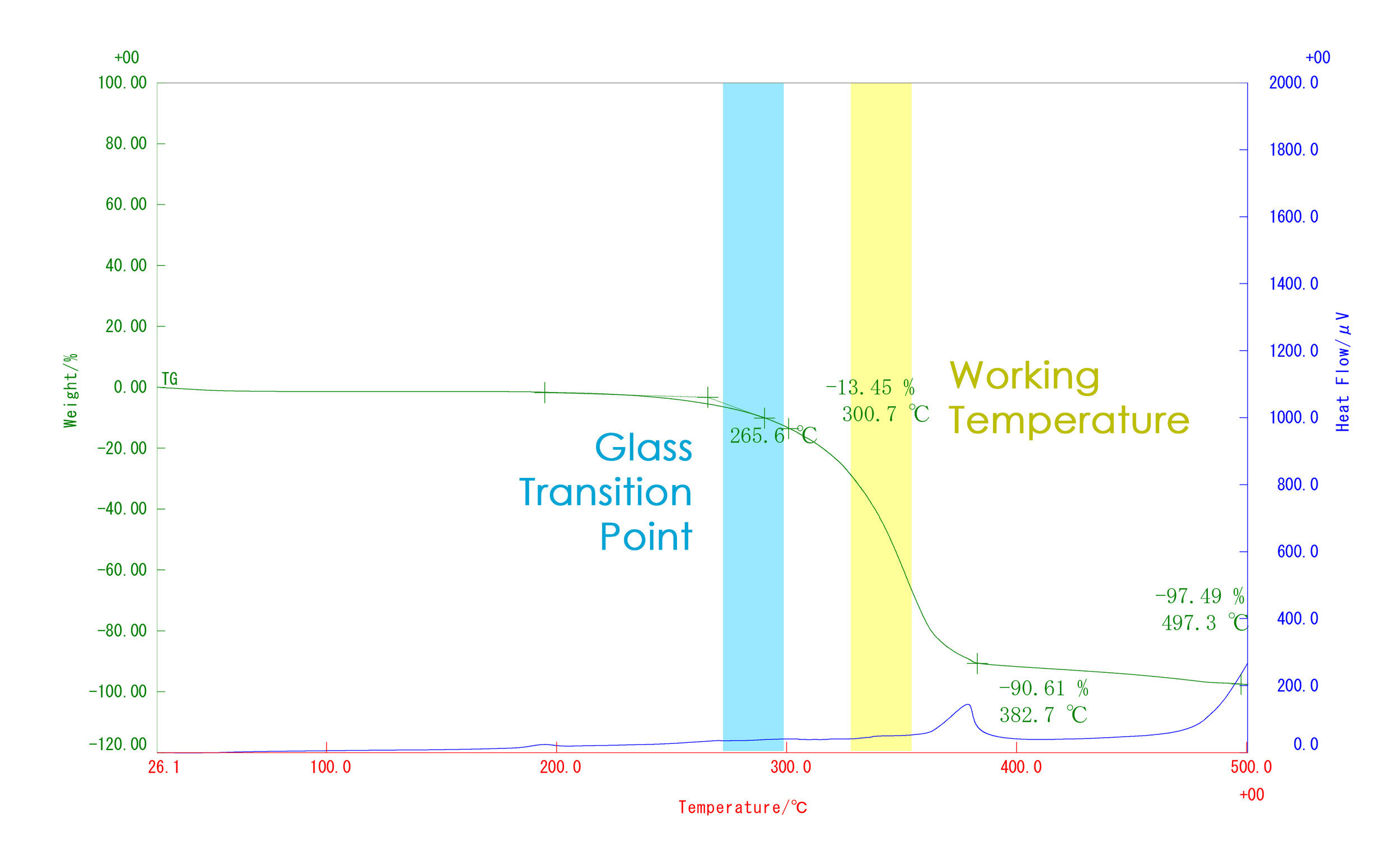

Fig. Existing Vehicle Combustion

Ethylcellulose and acrylic vehicles used in conventional glass pastes have already been vitrified in the temperature range of the firing process of the de-vehicles, including the vehicles and significantly reducing reliability.

Therefore, our company aims to develop a vehicle that can be used in this low-temperature sintering YPF-002 Model. The combustion start temperature of the conventional vehicle is around 265℃ and the combustion slow down is around 382℃.

Since the vitrification transition point of YPF-002 is 280-300℃ and the sealing temperature is 330-350℃, many vehicles will remain when sealed.

_Development of Vehicles_

As a conventional vehicle structure, a cyclic carbon bond and a side chain containing an alkyl group are formed. Therefore, in order to reduce combustion temperature, adhesive with low carbon number such as straight chain structure and side chain is developed.

Fig. Developed Vehicle Combustion

| - | Combustion Start | Slow combustion | Remain at 300℃ | 98% Residual |

| Existing Binder | 265.6℃ | 382.7℃ | 86.55% | 497.3℃ |

| Developed Binder | 249.8℃ | 314.9℃ | 12.26% | 314.9℃ |

The adhesive developed has reduced the starting temperature of combustion and accelerated the combustion speed.

:: Paste Development Review ::

When Paste of YPF-002 was made with the developed binder, problems arose that precipitation could easily occur due to separation. The main reason for this is that the glass structure and adhesive do not bind well due to the straight chain structure.

Therefore, in order to solve the settling problem, the method of reducing the settling speed of YPF-002 by controlling the particle size of YPF-002 and the kneading process of YPF-002 and adhesive is more than twice as long as before.

Fig. Existing vehicle

Fig. Developed vehicles

Fig. Developed vehicles

& process change

The developed product can be used stably by rolling it at about 10 rpm for an hour before use.

:: Paste Production ::

Glass Preform

Glass Paste

Sodalime Glass Bonding

_Application_

Low temperature sealing material for ceramic packaging

Adhesive materials for nonwoven adhesives

Metal-ceramic bonding

Automobile-related sensors

Replacement materials for acrylic adhesives

Airtight sealing of optical fiber

Resin flame retardant

_Recommended Terms of Use_

| ① Heating | ② Dry | ③ Curing | ④ Cooling | ⑥ Heating | ⑦ Sealing |

| 5~10℃/min | 130℃ * 20min | 280℃ * 60min | 15~20℃/min (Natural Cooling) |

10~20℃/min | 330-350℃ |

In Paste's drying and Curing process, N2 atmosphere and atmosphere can be used, but N2 atmosphere can further promote adhesive combustion. When sealing, please do it in an N2 atmosphere.