Precision Glass Processing

From Raw Glass to High-Performance Glass Components

“Custom-cut, optically polishing, Tempering glass, and Special purpose coating”

YEKGLASS provides total glass processing services tailored to your industrial needs.

One-Stop Glass Processing Services

YEKGLASS offers full-spectrum glass processing from material sourcing to surface finishing.

Whether you're building inspection windows, optical panels, or custom shaped glass parts, our processing expertise ensures high-performance across your application.

| Process Step | Description | Typical Spec |

|---|---|---|

| Material Selection | Choose from glass materials for needs | BOROFLOAT, Sodalime, Eagle-XG, OA-10, AN100 |

| Precision Cutting | High-accuracy cutting for custom shapes and sizes | ±0.3 mm, ±T0.01 mm tolerance |

| Optical Polishing | Surface flattening and roughness control for optics | TTV < 10 μm, Ra < 1 nm, MIL 40/20 |

| Glass Strengthening | Heat or chemical treatment to improve durability | ASTM-compliant strengthened glass |

| Functional Coatings | AR, IR, and filter coatings for optical performance | <0.5% reflectance, λ range 400–1100 nm |

| Cleaning & Packaging | Clean delivery for contamination-sensitive uses | Delivered in particle-free sealed trays |

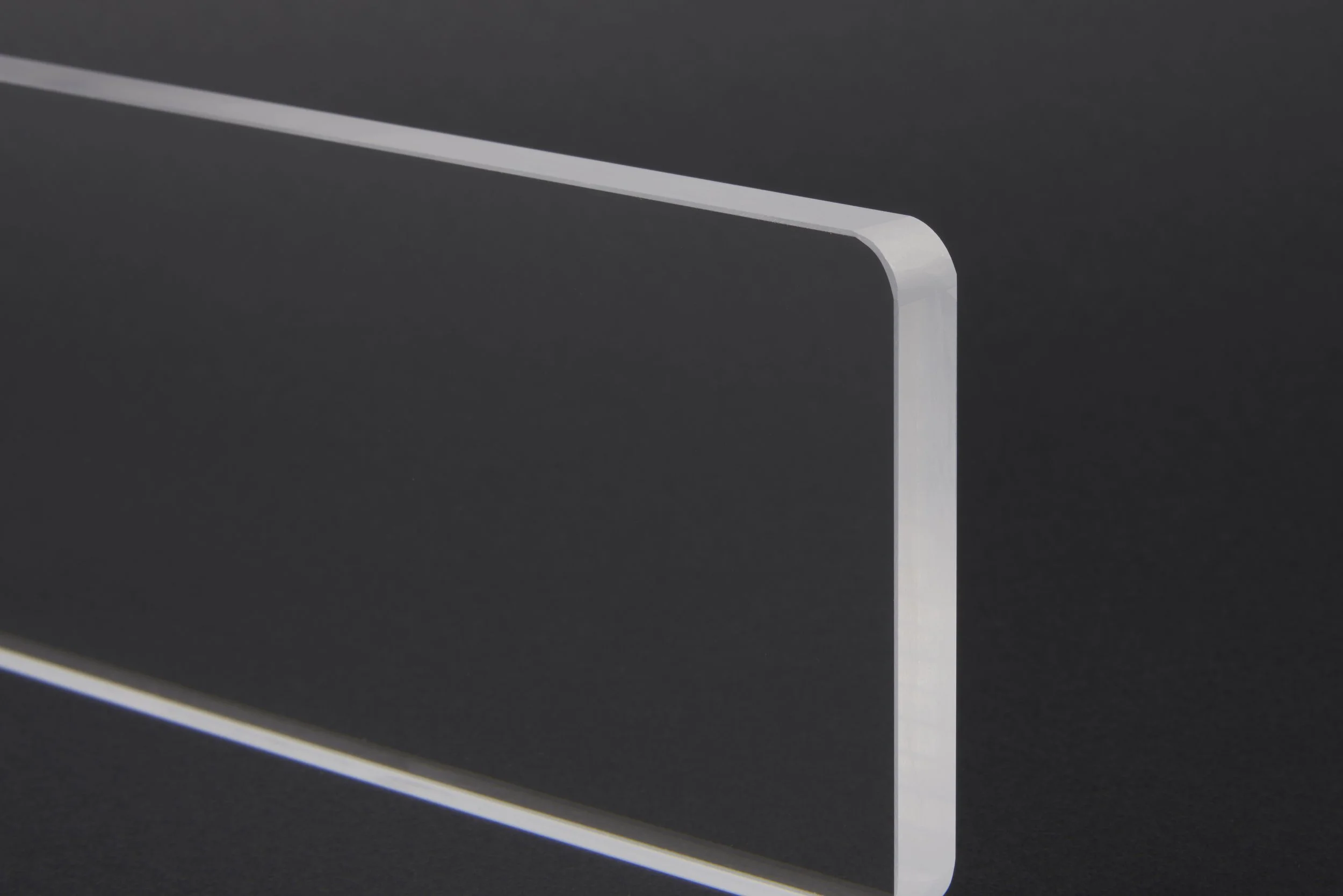

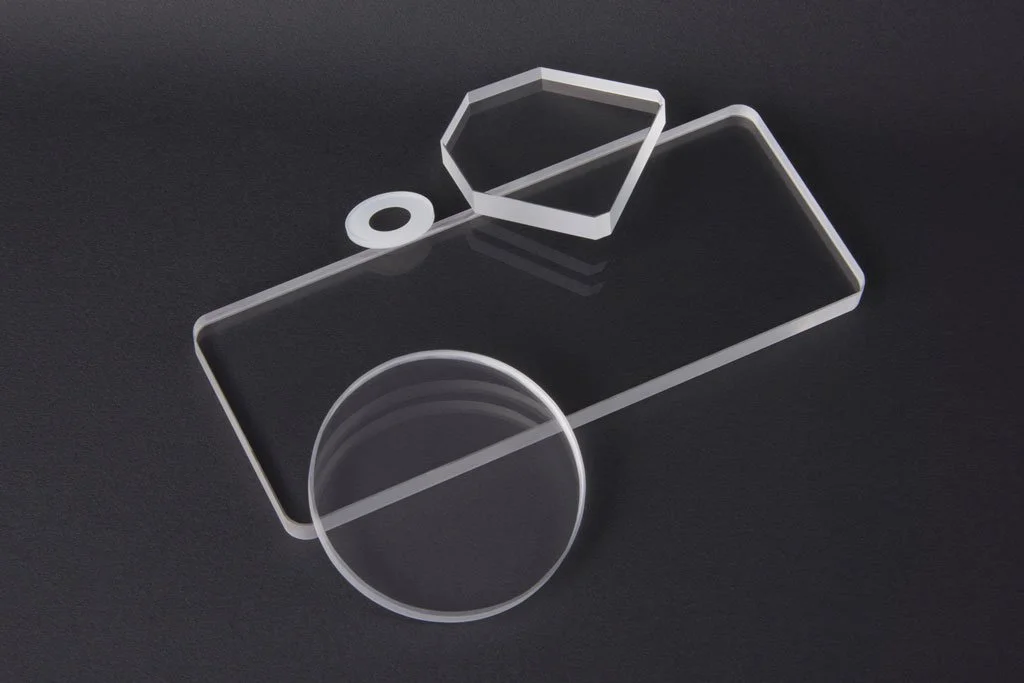

Custom-Cut Glass

Fabricated to exact dimensions, shapes, and tolerances based on client specifications.

Optical Polishing

Achieving ultra-smooth surfaces for high-transmission and low-scattering applications such as sensors, optical windows, and laser systems.

Tempering Glass

Enhancing mechanical durability and thermal resistance through controlled heat treatment processes.

Special-Purpose Coatings

Including Anti-Reflection, Bandpass Filtering, IR/UV blocking, Conductive ITO, and hydrophobic coatings applied to meet functional and environmental requirements.

Applications That Rely on Precision

Where Ultra-Precise Glass Makes a Difference

From semiconductor inspection to optical instrumentation and harsh-process equipment, precise glass components are essential for performance and reliability. YEKGLASS delivers custom-fabricated glass solutions tailored to each application’s thermal, mechanical, and optical demands.

| Industry | Application Use Case | Function / Requirement |

|---|---|---|

| Semiconductor | Etcher / PECVD Window | High-temperature resistance, plasma durability |

| Display Equipment | OLED deposition chamber glass | AR coating, thermal resistance, easy inspection |

| Battery Production | Roll-to-roll process windows | Thermal stability, scratch resistance |

| Laser & Optics | Laser-safe protective window | Precision flatness, bandpass/IR coatings |

| Pharmaceutical | Sterile line inspection window | Chemical resistance, smooth polish, visibility |

| Vacuum Equipment | Viewport on vacuum chamber | Low outgassing, reinforced structure |

| Food & Beverage | Process line safety windows | Anti-fog, impact resistance, hygienic polish |

Have a drawing, sample, or just a rough idea?

Share your specifications and we’ll provide a customized solution from material selection to coated, polished delivery.

Request a Quote for Your Custom Glass Part

Why Choose YEKGLASS?

Precision, Customization, and Proven Performance — All in One Place

With over 45 years of experience in advanced glass processing, YEKGLASS delivers more than just fabrication.

We work as your manufacturing partner — providing precision-cut, polished, strengthened, and coated glass tailored to your needs.

From cleanroom-ready optical panels to high-temperature resistant equipment windows, our expertise spans industries and applications.

Whether you need small-batch prototypes or full-scale production, we ensure quality, consistency, and responsiveness every step of the way.

Need Engineering Guidance Before You Start?

Not sure what glass material or coating fits your equipment?

Our team can help evaluate your application and recommend the optimal processing approach..