Next-Generation Phosphor Solution for High-Power LEDs

Solid-State Phosphor Encapsulation for Harsh Environments

It is specifically designed for high-power LED applications where long-term reliability is critical.

Compared to traditional silicone binders, PiG offers significantly improved color stability.

Our custom low-temperature frit technology allows safe sintering of red phosphors that are otherwise vulnerable to heat.

As a result, YEKGLASS PiG chips provide a stable and dependable solution for advanced LED lighting systems.

Why Replace Phosphor in Silicone with PiG?

Glass-Based Stability for Long-Term Performance

PiG is a solid-state phosphor solution that solves the reliability issues commonly found in silicone binders.

While PiS materials degrade under high temperatures and humidity, PiG maintains its structural and optical integrity over time.

| Property | PiS (Silicone) | PiG (Glass) |

|---|---|---|

| Heat Resistance | Low | High (Over 400 °C) |

| Moisture Resistance | Poor | Excellent |

| Durability | Weak over time | Long-Term Stable |

| Luminous Stability | Degrades with current | Maintains peak output |

| Suitable for | Low-power LEDs | High power, Automotive, Industrial LEDs |

Application Fields

Trusted in the Toughest LED Environments

Where Reliability Meets Performance

Automotive (Headlamp, DRL, Signal)

Horticulture (660nm Deep Red)

COB & DOB Modules

Medical Specialty Lighting

PiG Engineering Capabilities

Broad Experience in Custom PiG Development

YEKGLASS has extensive experience developing Phosphor in Glass solutions tailored to specific customer needs and LED system requirements.

We offer full control over phosphor type, chip size, thickness, and sintering profile ensuring consistent optical performance and compatibility with your final application.

| Parameter | Specification |

|---|---|

| Phosphor Types | CaAlSiN₃:Eu²⁺, YAG:Ce³⁺, LuAG:Ce³⁺, α-SiAlON:Eu²⁺ and more |

| PiG Chip Size | Min 4 μm to 4" Wafer |

| Thickness | Min 50 μm to 2 mm |

| Tolerance | ±10 μm |

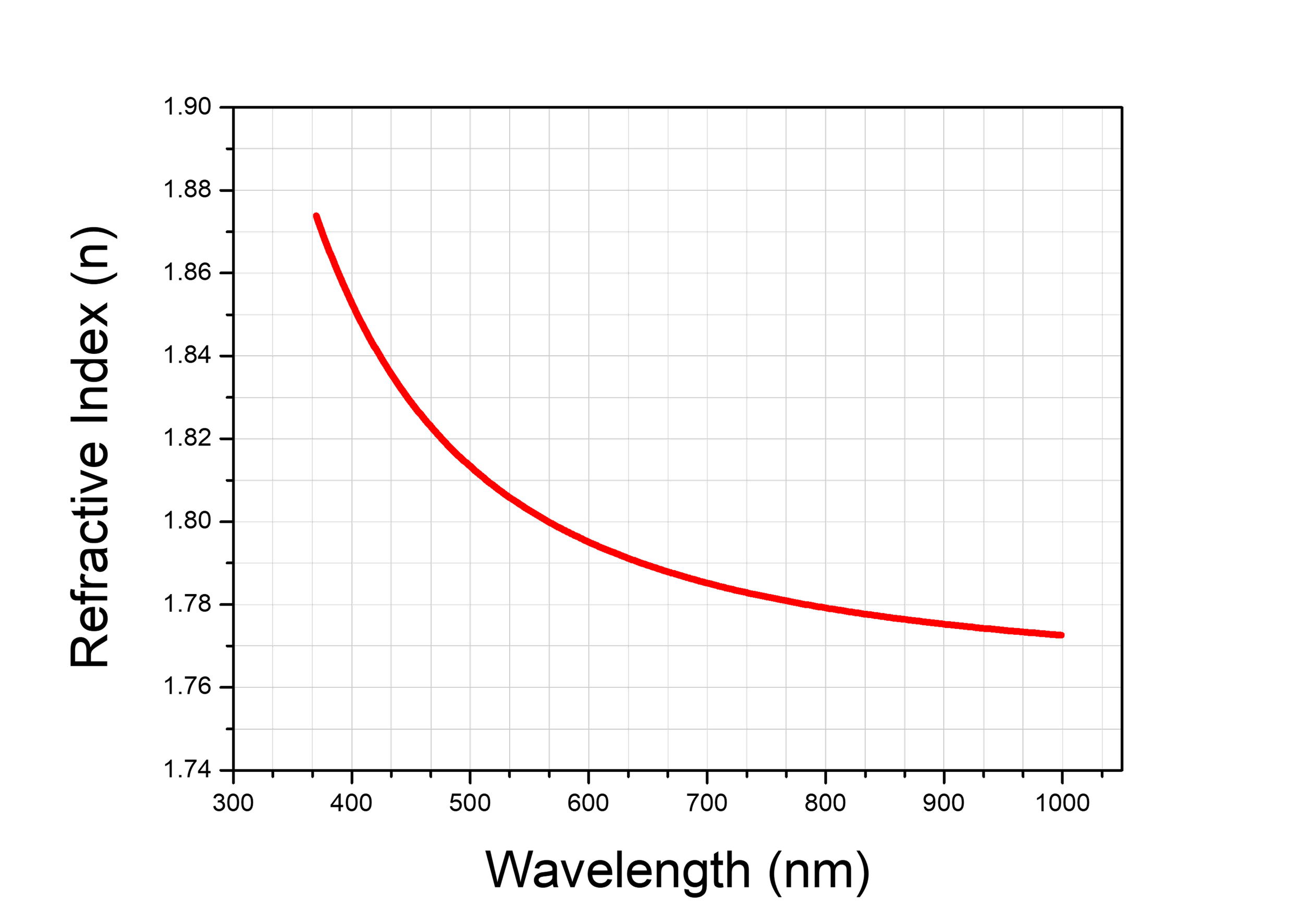

| Refractive Index | > 1.82 (@450 nm) |

We tailor PiG compositions to meet your luminous efficiency, color target, and thermal performance requirements.

Our team is ready to help you evaluate material compatibility, optimize phosphor encapsulation, and meet color stability targets.

Contact us to discuss your LED application or request a custom PiG sample.

Have Questions About Red PiG Performance?

Red Phosphor Compatibility

Thermal-Safe Red PiG with Custom Low-Temperature Glass

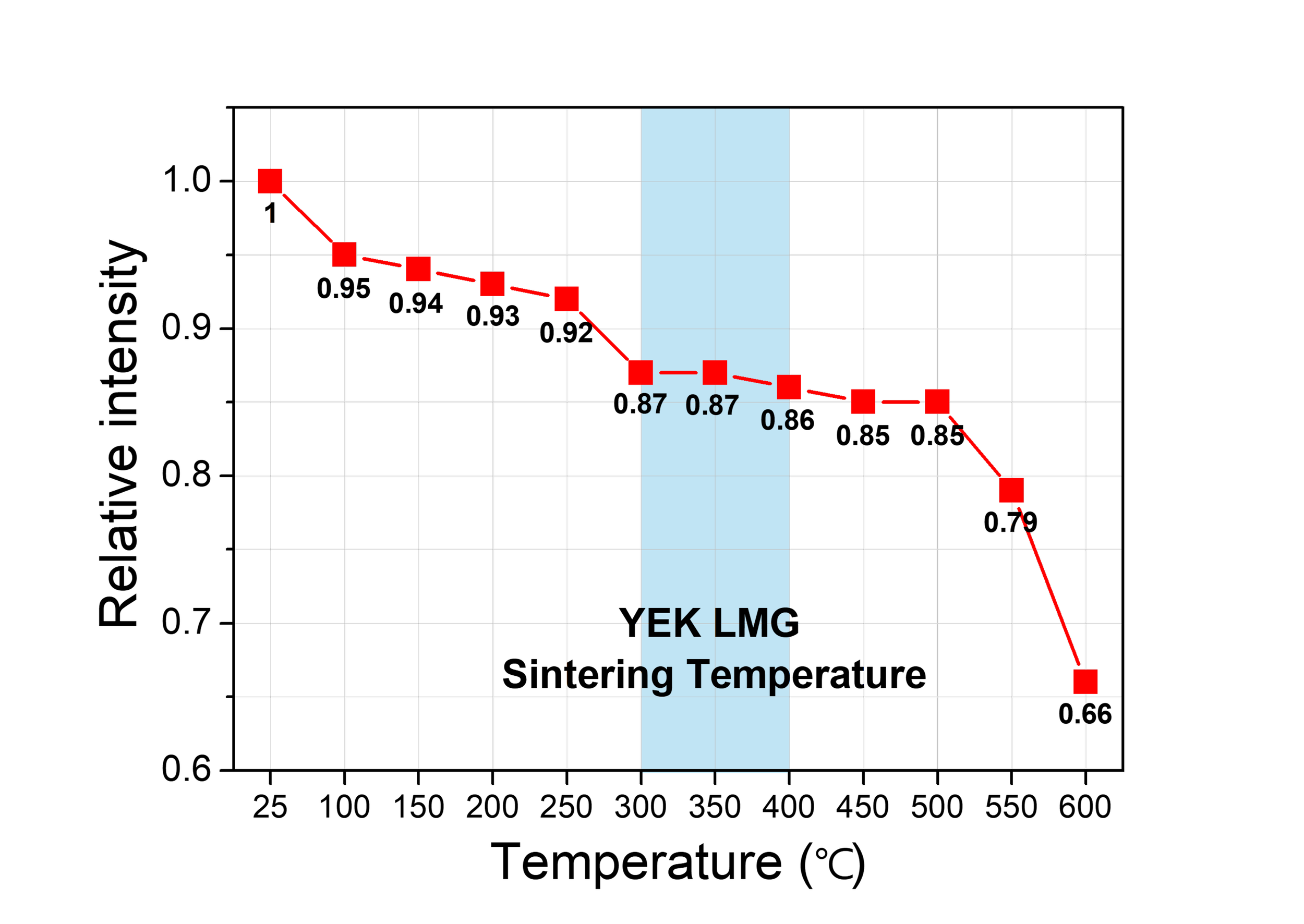

Red phosphors like CaAlSiN₃:Eu²⁺ are highly sensitive to heat and easily degrade in traditional sintering environments.

YEKGLASS solves this challenge by using specially formulated Low Melting Glass, which enables PiG sintering at just 250–350 °C.

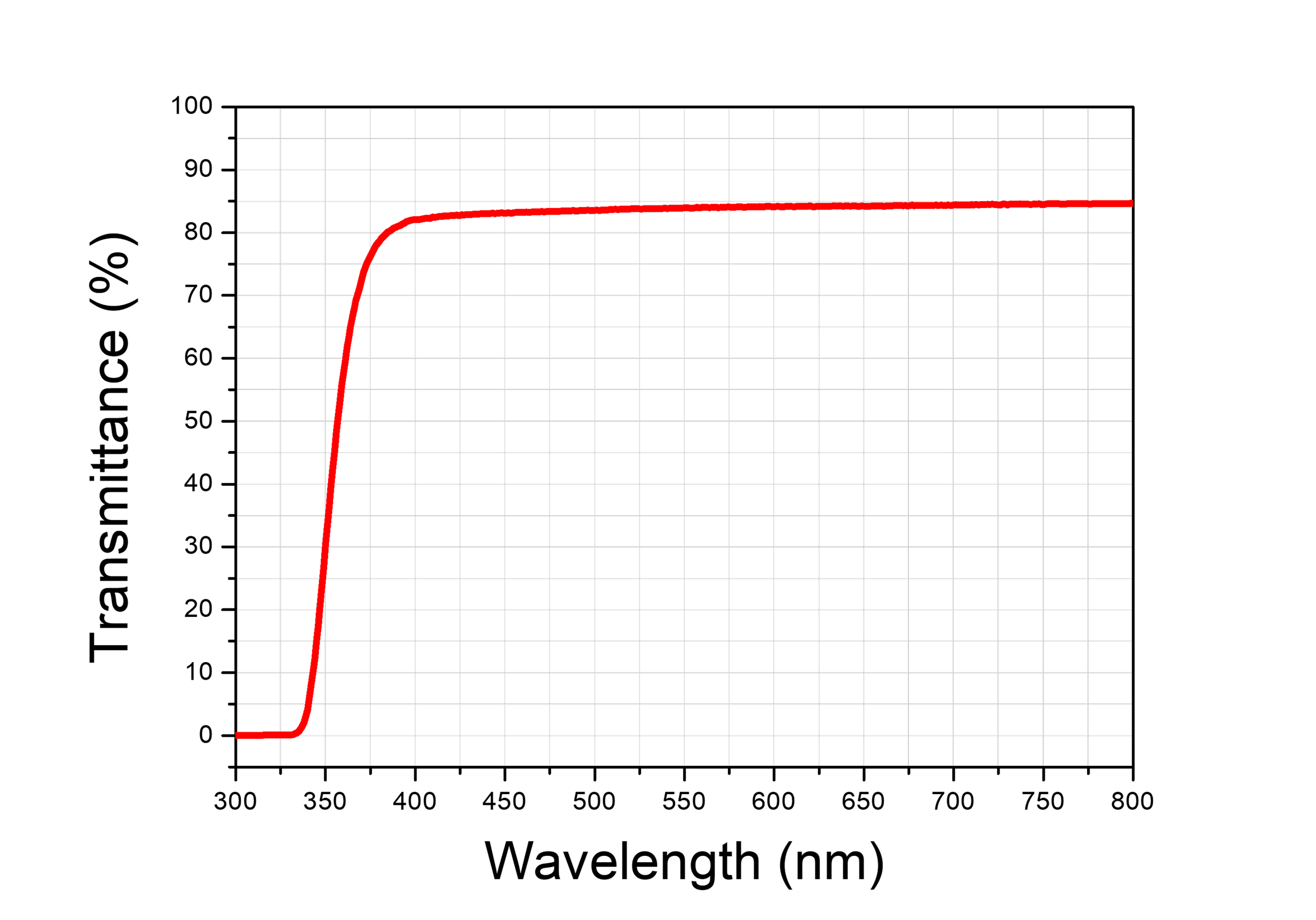

“High transmittance and refractive index in the blue-violet region enhances LED photoluminescence efficiency.”

YEK Glass’s low-melting glass material is engineered for optimal optical performance.

This ensures strong photoluminescence and allows safe sintering of heat-sensitive red phosphors without degradation.

“Thermal stability and low glass transition enable sintering at reduced temperatures.”

| Model | Tg (°C) | *Tw (°C) | CTE (×10⁻⁷/°C) | D50(μm) | Type |

|---|---|---|---|---|---|

| YPF Series for PiG | 290 ± 10 | 310–350 | 115 ± 10 | 10 ± 5 | Transparent(N₂) |

Ready to Start Your PiG Project?

YEKGLASS supports full-cycle development from formulation to chip production.

Get in touch to request specs, timeline, or quotation.