Since 1978

Precision Glass Solutions Engineered for Industry

From sealing glass frit to microstructured wafers, we build functional glass you can trust.

Pioneering Functional Glass Since 1978

Proven by our work with top-tier display, LED, and semiconductor equipment manufacturers.

From precision sealing to semiconductor integration, YEKGLASS leverages over 45 years of glass engineering expertise to solve the industry's most demanding material challenges.

Partner with us for your next breakthrough

We thrive on challenges.

Contact us today — our project manager will connect with you to explore what’s possible.

Glass Solutions for High-Tech Industries

We serve a wide range of industries with precision glass components designed for critical functions and environments.

MEMS & Sensors Component

YEKGLASS supplies precision glass wafers, substrates, and molded components for MEMS and sensor integration. Our low temperature frit enables hermetic bonding of delicate structures, including TGV and cavity designs, while maintaining high dimensional stability and process compatibility.

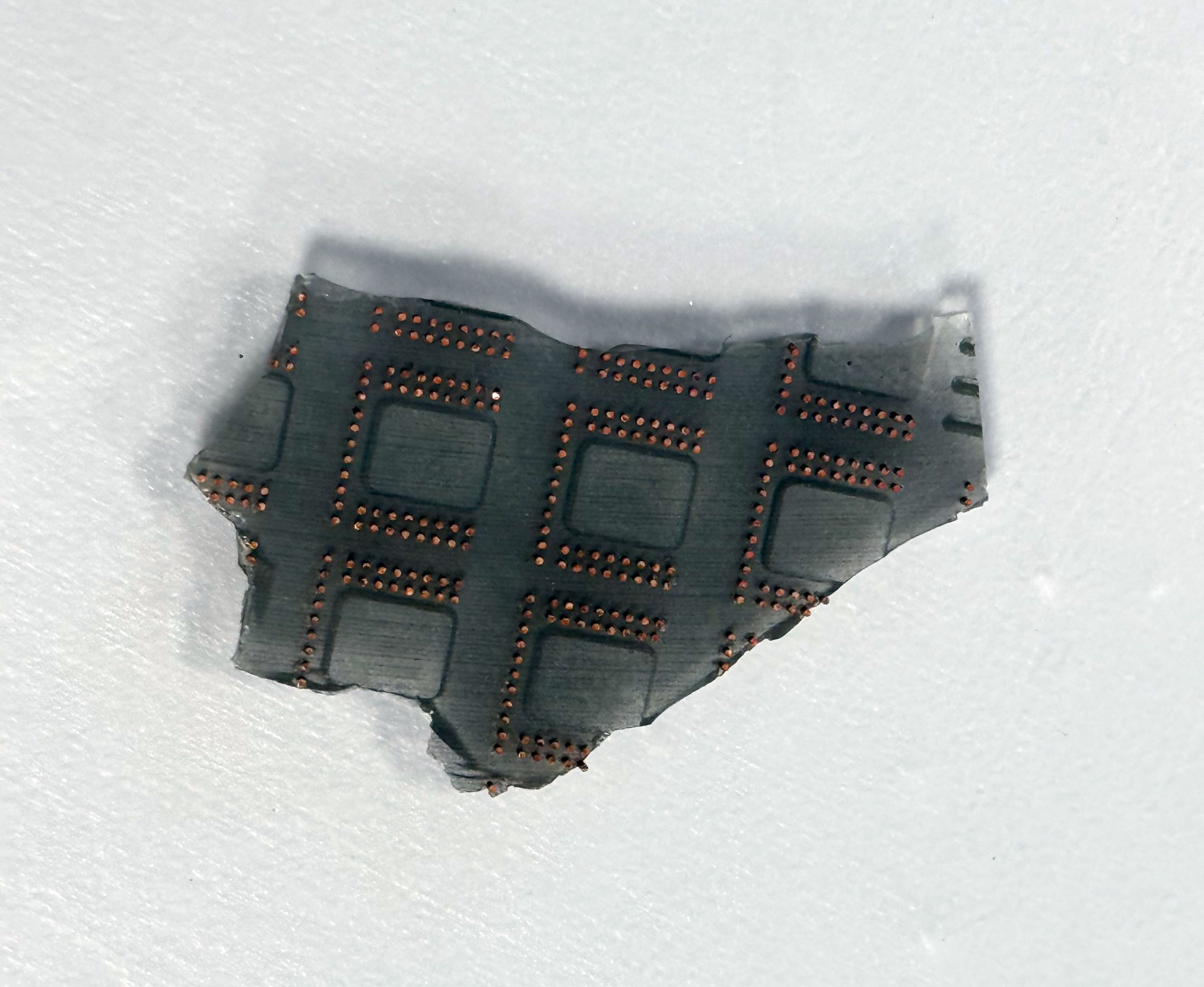

Semiconductor Packaging

We offer high precision glass interposers and wafers with TGV and cavity structures for 2.5D and 3D integration. Our solutions ensure thermal reliability and vertical connectivity for compact, high density chip packaging.

Process Equipment Windows

We supply durable, optically clear glass windows for high temp, high pressure equipment. Options include AR or band pass coatings and custom sizes for display, semiconductor, and battery lines.

LED Packaging

Our phosphor in glass materials offer superior thermal stability and consistent luminous output for high power LEDs. Ideal for automotive, industrial, and specialty lighting with customizable phosphor types and thickness.

Biochip & Microfluidics

YEKGLASS produces microfluidic glass chips with molded channels and wells for diagnostics, ELISA, and lab on chip devices. We support rapid prototyping and high chemical resistance.

R&D Collaboration

We work closely with research teams, startups, and developers to create tailored glass solutions through rapid prototyping and technical consultation. Whether you're exploring new concepts or refining a design, our team is ready to support your innovation journey.

Explore Our Core Glass Technologies

YEKGLASS delivers high performance glass materials across five specialized product lines.

Glass Frit & Paste

YEK’s glass frit and paste are engineered for high integrity bonding between a wide range of materials. Designed for low temperature processing and tailored thermal expansion, our formulations support stress free, hermetic sealing in sensors, microelectronic packages, and optical modules-enabling durable protection against moisture and environmental stress.

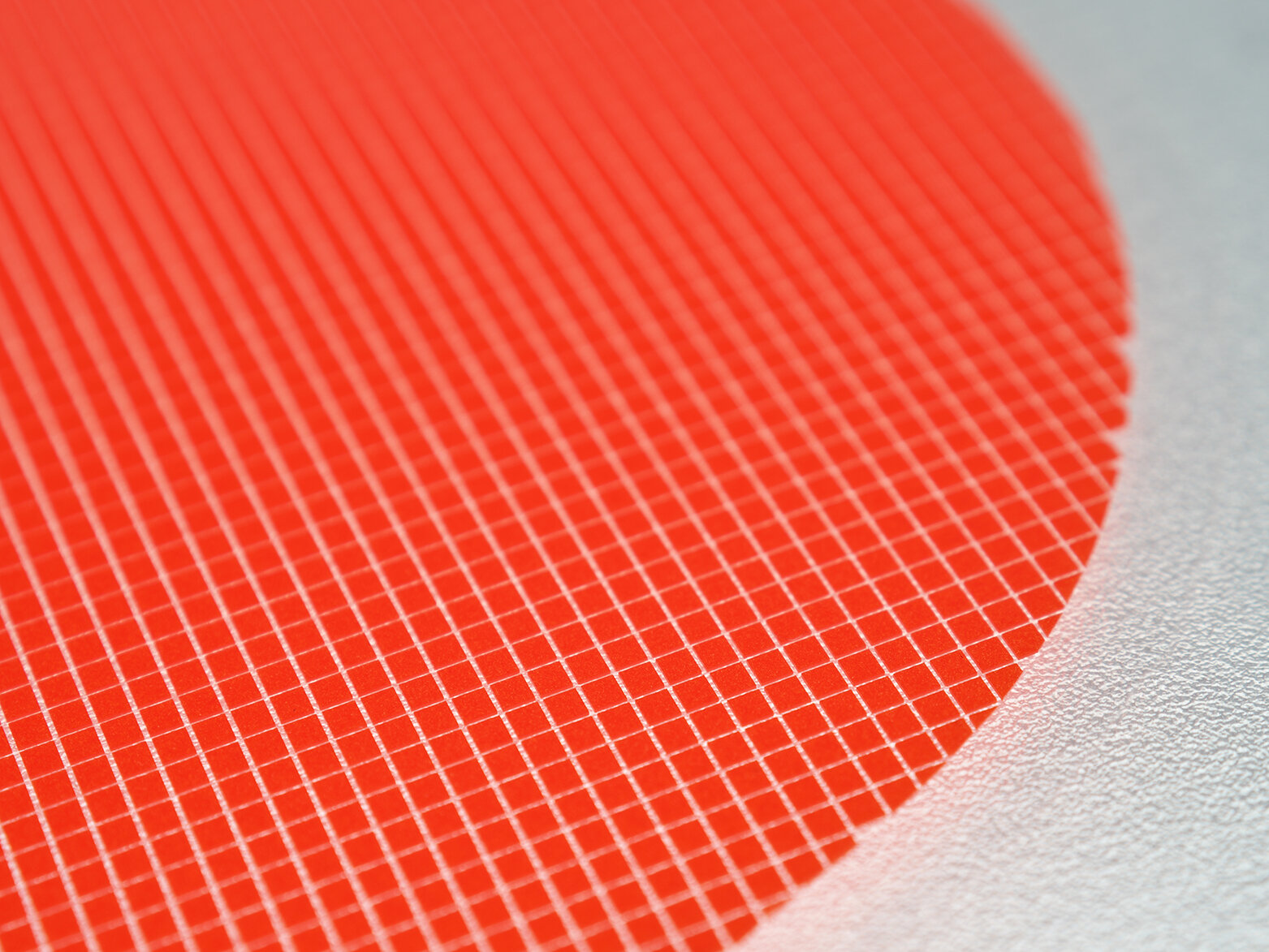

Glass Wafer Processing

Our high purity glass wafers deliver excellent dimensional stability, ultra-low TTV, and smooth surface quality. Tailored for TGV (Through Glass Via), 2.5D/3D integration, or temporary carrier applications, these wafers enable high density interconnects, clean processing, and compatibility with next generation semiconductor packaging.

Precision Glass Processing

From ultra flat windows to multi functional substrates, YEK offers complete in-house processing including CNC machining, ultrasonic cleaning, and thin film coating. Our capabilities support demanding use cases in display manufacturing, semiconductor equipment, optical instrumentation, and aerospace components.

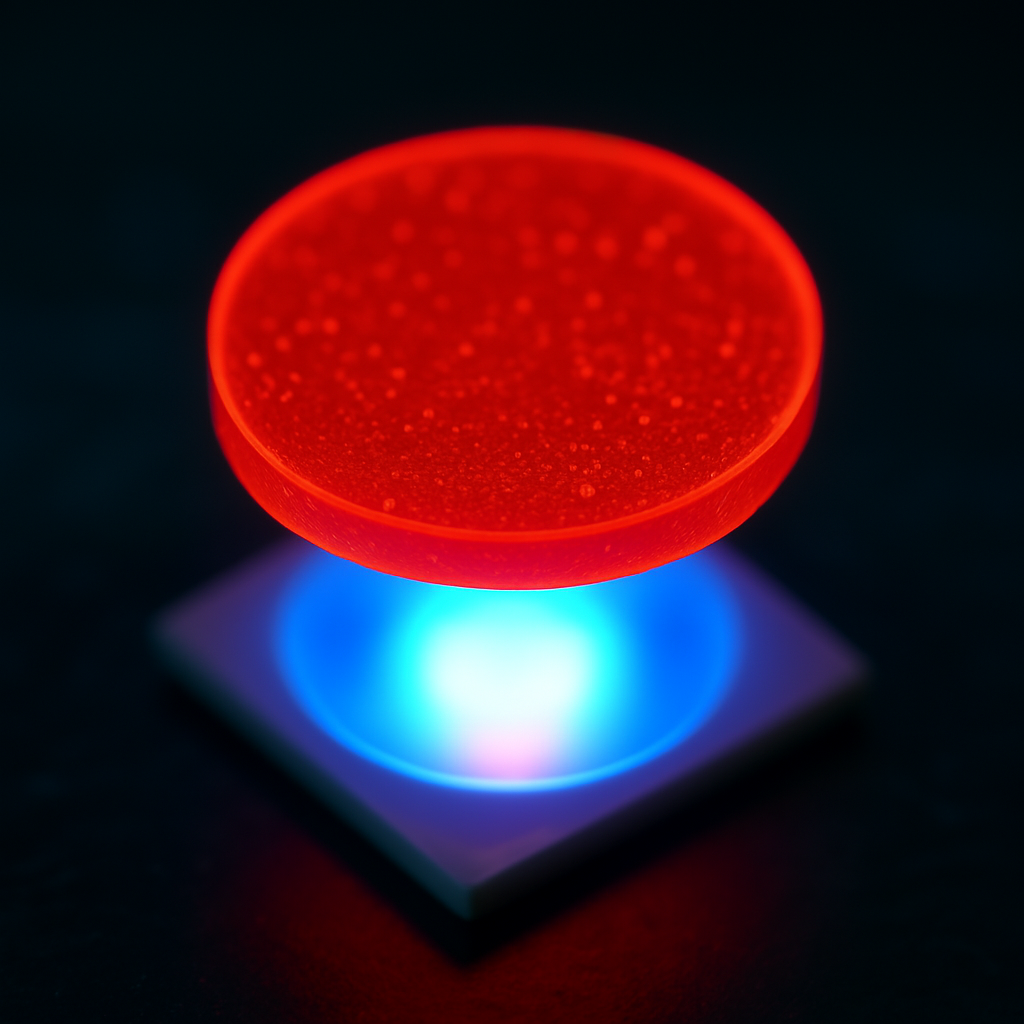

Phosphor in Glass

YEK’s PiG solution embeds phosphor particles in low-melting-point glass to achieve excellent heat dissipation and chemical stability. Designed for high power LED modules, automotive lighting, and horticultural systems, it offers consistent luminous flux and spectral integrity under harsh operating conditions.

Request a Quote

Whether you need custom specifications, rapid samples, or a technical consultation—our team is ready to support your next innovation. We offer fast communication, engineering insight, and flexible production tailored to your needs. Contact us today for personalized guidance, pricing, and global delivery options.

Let’s create what the world hasn’t seen yet

We believe the most meaningful innovations start with imagination.

If you’re building something new, we’re ready to help make it real with our glass expertise.